Polyurethane fibers are referred to as “Spandex” as a generic name. The fiber itself is highly stretch and elastic as rubber, strong than rubber, and resistant to aging. The fiber is dyeable freely and fine yarn can be produced.

Polyurethane fiber is manufactured from glycol and diisocyanate as raw material with a special spinning method.

No product is manufactured of 100% poly-urethane fiber. The polyurethane fiber is used by blending other fibers. A fabric, referred to “two-way tricot” in which a polyurethan fiber is knitted with a nylon or polyester filament yarn, is highly elastic both in wale- and course-way and is used for swimsuits, leotards, underwear and other similar stretchable clothing.

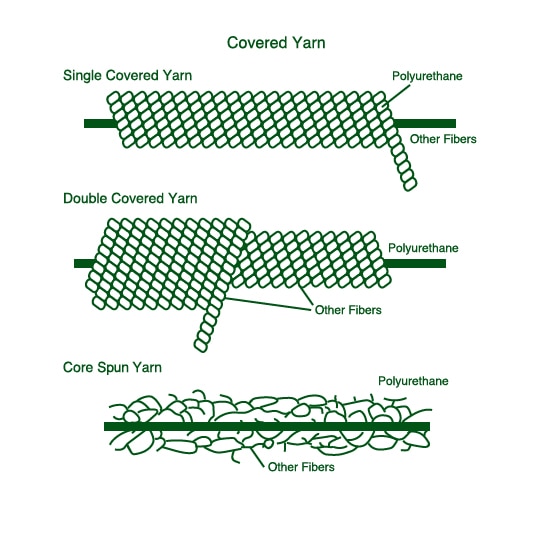

A yarn, in which another yarn such as nylon yarn is wound around polyurethane yarn is referred to as a “covered yarn”. A covered yarn is used for pantyhose and foundation garments. In addition, a yarn in which a polyurethane yarn is inserted as a core in the spinning process is referred to as a “core spun yarn”. A core spun yarn is used for tights and training wear.