Acrylic fibers have characteristics most similar to those of wool fibers. They are soft and light fibers having light and warm tactile feeling to the human skin. Acrylic fibers are widely used, making the most of their characteristics, for knitted products such as sweater and jersey; bedding textiles such as blankets and Pile sheets; and carpets for home-uses. In addition, rag animals and western wigs are the products making use of acrylic fibers.

Acrylic fibers are manufactured in a wide variety of characteristics such as those lustered, delustered, with soft tactile feeling, and with rigid tactile feeling. There are many other types of acrylic modified fibers such as animal-like fibers with oval cross-section, thermal resistant fibers, anti-pilling fibers, antibacterial and deodorant fibers, and anti-static fibers.

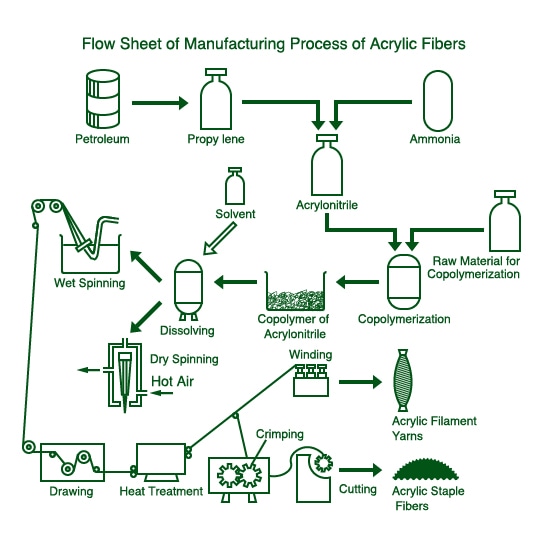

Acrylic fibers are manufactured in staple fibers, almost with a wet spinning process. However some fibers are manufactured with a dry spinning process. Such dry spun fibers have different fabric hand from that of wet spun fibers and are developing in a variety of new end-uses. Light/soft feeling, a characteristic among features of acrylic fibers, is referred to as bulkiness. Bulky spun yarns, difficult to spin other fibers, are available. A variety of yarns blended with other types of fibers such as cotton and wool fibers are manufactured to make use of characteristics of each type of fibers.

Filament yarns of acrylic fibers are also available. Since the filament yarns have luster and tactile feeling, they are used for silk-like knitted products. In addition, they are used for accessories for Japanese dresses and the field of silk products thanks to the non-yellowing. For information, acrylic fibers include acrylic fibers themselves and modacrylic fibers. Those fibers which contain (not less than 85%) acrylonitrile molecule as main component are “acrylic” fibers. On the other hand, those fibers which contain 35-85% acrylonitrile molecule are “modacrylic” fibers. Since modacrylic fibers are copolymerized with vinyl chloride or vinylidene chloride, they are flame retardant. They are used for curtains and wigs.